1. Set up welding equipment

Shielded

Metal

Arc Welding (SMAW) operation requires a setup and then weld.

•In general, the operator factor, or the

percentage of the operator’s time spent laying weld, is approximately 25%. The

rest is spent in preparation and in removing slag.

•The actual welding technique utilized

depends on the electrode, the composition of the workpiece, and the position of

the joint being welded.

•The choice of electrode and welding

position also determines the welding speed.

•Flat welds require the least operator

skill and can be done with electrodes that melt quickly but solidify slowly.

This permits higher welding speeds.

•Sloped, vertical or upside-down welding

requires more operator skill and often necessitates the use of an electrode

that solidifies quickly to prevent the molten metal from flowing out of the

weld pool.

•However, this generally means that the

electrode melts less quickly, thus increasing the time required to lay the

weld.

•Before starting make sure that you are

using

a good helmet for

SMAW welding as well as protective clothing.

•Clean

the workpiece

•Clamp

the work close to the weld

•Insert

the electrode into the insulated holder. Set amperage at levels recommended by

the electrode manufacturer.

•Determine

the best arc length. As a guideline the arc for a 1/16″ to 3/32″ diameter

electrode is 1/16″ (1.6mm). The arc length for a 1/8″ and 5/32″ electrode is

1/8″ (3mm).

•Have

a chipping hammer available to remove any slag and before doing a 2nd pass with

the weld.

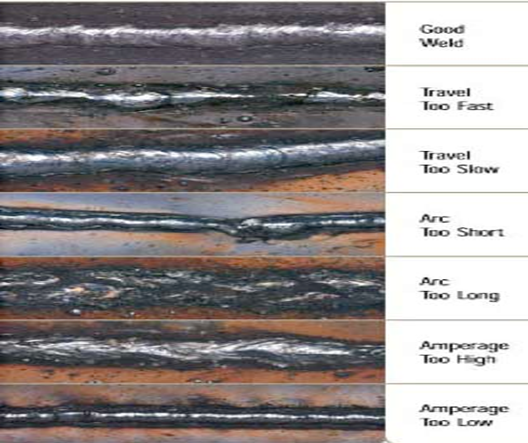

Poor weld bead characteristics include

large spatter deposits, use of the wrong arc, higher/lower amperage levels than

recommended and poor penetration.

Operation

Starting

the Arc

Scratch

Start Technique:

•To strike the electric arc when starting

a SMAW operation, the electrode is brought into contact with the workpiece,

dragged like lighting a match, and then pulled away slightly. If the arc lights

and then goes out, that means the electrode was pulled too far away from the

base metal. If the electrode sticks to the metal, give a twist and it should

come free.

Tapping

Technique:

•Move the electrode straight down to the

base metal. Then lift slightly. The arc should start. If the arc goes out, that

means it was lifted too high off the workpiece.

Operating

the Electrode Holder

•This initiates the melting of the

workpiece and the consumable electrode and causes droplets of the electrode to

be passed from the electrode to the weld pool.

•As the electrode melts, the flux covering

disintegrates, giving off a vapors that protect the weld area from oxygen and

other atmospheric gases.

•In addition, the flux provides molten

slag which covers the filler metal as it is travels from the electrode to the

weld pool.

•Once part of the weld pool, the slag

floats to the surface and protects the weld from contamination as it

solidifies.

Set

up welding accessories

What

is

Stick Welding?

•Stick welding is technically defined as

“Shielded Metal Arc Welding”. The term “stick welding” is a common slang term

that the welding industry has adopted because the electrode that welds the

metal comes in the form of a “Stick”.

•The simplest explanation of how stick

welding works. Stick welding is a form of welding that uses electricity to melt

a metal filler rod/electrode/stick (electrode is the proper term) that melts

both the metal joint and electrode all at once to fuse two pieces of metal

together and fill the joint with filler metal at the same time.

Stick Welding Equipment•Stick welding equipment is the simplest of all

the electrical arc welding processes. A Stick Welder has four parts:

•A

constant voltage (CV) power supply/Stick Welder.

•Electrode

holder/rod holder.

•Ground

clamp.

•Stick welding electrodes/rods to weld

with.

What is the Difference between

Stick, MIG and TIG Welding?

•Stick and

TIG welding use

the same Constant Voltage power supply and a Stick welder can be adapted to TIG

Weld just by adding a torch set-up.

Accessories

•welding

guns

•regulators

and flow meters

•gas

hoses and adaptors

•gas

cylinders and gas heaters

•filters,

gas nozzle and insulators

•wire

feeders and wire cutter

Set

up welding positioners, jigs and fixtures

Welding

Positioner

•The welding positioner is a practical

auxiliary positioner. It is mainly used in workplaces such as welding of steel

structures and assembly of mechanical parts. It is widely used in the

manufacturing industry of various steel structures such as flanges, pipe

joints, etc. It can also be used as peripheral equipment and a robot to achieve

automatic welding. It is one of the commonly used equipment in modern pipeline,

container and steel structure manufacturing enterprises.

JIGS & FIXTURES

Generally, it is a work holding device

that holds, supports and locates the work piece for a specific operation but

does not guide the tool. It provides only a reference or a device. What makes a

fixture is that each one is built to fit a particular part or shape. The main

purpose of a fixture is to locate and hold a work piece during either a

machining operation or some other industrial process. A jig differs from a

fixture in that as it guides the tool to its correct position in addition to

locating and supporting the work piece. In welding their main function is to

position components accurately, hold components rigidly and prevent movement

during working in order to ensure greater productivity and part accuracy. Jigs

and fixtures are especially designed so that large no. of components can be

machined or assembled identically and to ensure interchangeability of

components. It promotes good fitting tolerance in the final product and the

quality of work piece is very high which are produced at low cost.