•Tack

welding involves welding two or more metal pieces together by

merely applying pressure and heat to the area to be welded. Tack

welding joins the two pieces of metal by using electrodes to send

electrical current through the work pieces. The parts are locally heated.

•After items to be welded together have

been positioned as required, generally by clamping them on suitable fixtures,

tack welds are used as a temporary means

to hold the components in the proper location, alignment, and distance apart,

until final welding can be completed.

•In general, tack welding is performed by

the same process that is used for the final weld. For example, aluminum-alloy

assemblies to be joined by friction stir welding are tack-welded by the same

process using a small tool developed for this purpose. Or electron beam tack

welds, created with reduced power, are used to supplement or replace fixturing and

to maintain the correct shape and dimensions during final electron beam

welding.

Why are Tack Welds Important?

The temporary

nature of tack welds may give the false impression that the quality of these

auxiliary joining aids is not as important as that of final weld and that this

operation doesn't have to be properly programmed, performed, and inspected.

This is not true.

Tack

welding is real welding, even if the welds are deposited in separate short

beads. It performs the following functions:

•Holds

the assembled components in place and establishes their mutual location

•Ensures

their alignment

•Complements

the function of a fixture, or permits its removal, if necessary

•Controls

and contrasts movement and distortion during welding

•Sets

and maintains the joint gap

•Temporarily ensures the assembly's

mechanical strength against its own weight if hoisted, moved, manipulated, or

overturned

Defective Tack Welding Risks

•When hoisted, improperly tack welded

assemblies can rupture, and portions or subassemblies can fall and endanger

people or damage property.

•Tack welding must not interfere with or

degrade the quality of final welding. It must not introduce weld defects, such

as arc strikes, craters, cracks, hard spots, and slag left in place.

•Many steels used in fabricating pipes and

vessels are sensitive to rapid cooling or quenching, especially following short

tack welds, because of the limited heat input required to tack weld.

Note:

Higher

heat input slows the cooling rate, which minimizes the occurrence of hard and

brittle microstructures.

Check gap alignment

•To ensure the satisfactory performance of a

welded structure, the quality of the welds must be determined by adequate

testing procedures. Therefore, they are proof tested under conditions that are

the same or more severe than those encountered by the welded structures in the

field.

•These tests reveal weak or defective sections

that can be corrected before the materiel is released for use in the field. The

tests also determine the proper welding design for ordnance equipment and

forestall injury and inconvenience to personnel.

In

most welds, quality is tested based on the function for which it is intended.

If you are fixing a part on a machine, if the machine functions properly, then

the weld is often considered correct. There are a few ways to tell if a weld is

correct:

•Distribution:

Weld material is distributed equally between the two materials that were

joined.

•Waste: The

weld is free of waste materials such as slag. The slag after cooling should

peel away from the project. It should be removed easily. In Mig

welding, any residue from the shielding gas should also be removed with little

problem.

TIG,

being the cleanest process, should also be waste free. In Tig, if

you see waste, it usually means that the material being welded was not cleaned

thoroughly.

Porosity: The

weld surface should not have any irregularities or any porous holes (called

porosity). Holes contribute to weakness. If you see holes it usually indicates

that the base metal was dirty or had an oxide coating. If you are using Mig or

Tig,

porosity indicates that more shielding gas is needed when welding.

Porosity in aluminum welds is a key indicator of not using enough gas.

•Tightness: If

the joint is not tight, this indicates a weld problem. In oxyacetylene welding,

if using autogenous welding, where there is no filler material, the weld must

be tight. Same for Tig

autogenous welding. The gap is not as critical in other types of welds since

any gap is filled in by the filler material. That said, gaps, in general,

indicate a potential quality problem.

•Leak-Proof: If

you are repairing an item that contains liquid, a leak is a sure-fire way (and

obvious way) to see that there is a problem. Same for something that will

contain a gas. One testing method is to use soap bubbles to check for problems

(can be easily applied with a squirt bottle.

•Strength:

Most welds need to demonstrate the required strength. One way to ensure proper

strength is to start with a filler metal and electrode rating that is higher

than your strength requirement.

Common Weld Faults

Incomplete

Penetration

This

term is used to describe the failure of the filler and base metal to fuse

together at the root of the joint. Bridging occurs in groove welds when the

deposited metal and base metal are not fused at the root of the joint. The

frequent cause of incomplete penetration is a joint design which is not

suitable for the welding process or the conditions of construction. When the

groove is welded from one side only, incomplete penetration is likely to result

under the following conditions.

•The

root face dimension is too big even though the root opening is adequate.

•The

root opening is too small.

•The

included angle of a V-groove is too small.

•The

electrode is too large.

•The

rate of travel is too high.

•The welding current is too low.

Lack

of Fusion

Lack

of fusion is the failure of a welding process to fuse together layers of weld

metal or weld metal and base metal. The weld metal just rolls over the plate

surfaces. This is generally referred to as overlap. Lack of fusion is caused by

the following conditions:

•Failure

to raise to the melting point the temperature of the base metal or the

previously deposited weld metal.

•Improper

fluxing, which fails to dissolve the oxide and other foreign material from the

surfaces to which the deposited metal must fuse.

•Dirty

plate surfaces.

•Improper

electrode size or type.

•Wrong current adjustment.

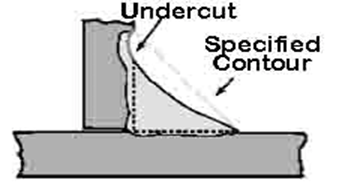

Undercutting

•Undercutting is

the burning away of the base metal at the toe of the weld. Undercutting may be

caused by the following conditions:

•Current

adjustment that is too high.

•Arc

gap that is too long.

•Failure

to fill up the crater completely with weld metal.

Slag Inclusions

Slag inclusions

are elongated or globular pockets of metallic oxides and other solids

compounds. They produce porosity in the weld metal. In arc welding, slag

inclusions are generally made up of electrode coating materials or fluxes. In

multilayer welding operations, failure to remove the slag between the layers

causes slag inclusions. Most slag inclusion can be prevented by:

•Preparing

the groove and weld properly before each bead is deposited.

•Removing

all slag.

•Making

sure that the slag rises to the surface of the weld pool.

•Taking

care to avoid leaving any contours which will be difficult to penetrate fully

with the arc.

Porosity

Porosity

is

the presence of pockets that do not contain any solid material. They differ

from slag inclusions in that the pockets contain gas rather than a solid.

• The gases forming the voids are derived form:

•Gas

released by cooling weld because of its reduced solubility temperature drops.

•Gases

formed by the chemical reactions in the weld.

•Porosity is best prevented by avoiding:

•Overheating

and undercutting of the weld metal.

•Too

high a current setting.

•Too

long an arc.

Visual Inspection before Welding

•Check

drawings

•Look

at the weld position and how it corresponds to the specification. Watch the

vertical direction of travel

•Does

the procedure align with local codes and the weld specification

Weld

Material Inspection

•Do

the materials purchased match the specification for base metal size and type?

Check electrode size, gas selection and grade.

•Check

materials for defects. Look for contaminants such as rust, scale, mill,

lamination etc.

•Are

materials prepared for correct angles

Equipment

Inspection

•Check

for damage (cables, ground clamps, electrode holder).

•Check

arc voltage

•Check

amperage meter for range against specification

Visual

Inspection

during Welding

•Check

electrodes for size, type and storage (low hydrogen electrodes are kept in a

stabilizing oven)

•Watch

root pass for susceptibility to cracking

•Inspect

each weld pass. Look for undercut and required contour. Ensure the weld is

cleaned properly between each pass.

•Check

for craters that need to be filled

•Check

weld sequence and size. Gauges are used to check size.