Prepare Welds Materials

1. Preparing weld materials

HOW TO SET UP A CUTTING TORCH SAFELY AND EFFICIENTLY

The most commonly available cutting torch is the oxy-fuel or oxy

acetylene torch, and it is used to bond two pieces of metal together

using very high heat.

The oxy-fuel cutting process is accomplished by bringing the base

metal to a molten state, then introducing a high-pressure stream of

cutting oxygen. This will ignite and burn the metal as well as carry

away the slag or oxidizing residue.

SETTING UP EQUIPMENT (CUTTING)

Inspect the cone end, coupling nut, and torch head for dirt, dust, oil, grease, or

damaged parts. Dirt and dust can be removed with a clean cloth.

CAUTION: If oil, grease or damaged parts are detected, contact your authorized

service repair station for cleaning or repairs.

2. Inspect the cutting attachment cone end for missing or damaged “O” rings. There

MUST BE two (2) “O” rings on the cone end. Damaged or missing “O” rings can

allow gases to mix and will cause backfires or backlash. Severe damage can result.

3. Inspect the torch head. The tapered seating surface must be in good condition. If

dents, burns or burned seats are present, the seat must be resurfaced. If the torch

is used with poor seating surfaces, backfire or backlash may occur.

4. Connect the cutting attachment to the welding torch handle and

tighten the coupling nut, using hand pressure only. Wrench tightening

may damage “O” rings and create a faulty seal.

5. Select the required size and type of cutting tip. Inspect the tip

seating surfaces for damage. REMEMBER – these seating surfaces

prevent premature mixing of gases that can cause fires and explosions.

If the tapered seats on the tip are damaged, DON’T USE! Inspect the

pre-heat and cutting oxygen holes. Splatter can stick on or in these

holes. If holes are clogged or obstructed clean them out with proper

size tip cleaner.

6. Insert the tip in the cutting attachment head and tighten securely

with wrench (15 to 20 pounds pressure).

7. Follow cylinder and regulator safety and operating procedures.

8. Open the oxygen valve on the welding torch completely.

9. Open the preheat oxygen control valve on the cutting attachment

and adjust the oxygen regulator to the desired delivery pressure.

10. Close the preheat oxygen control valve.

11. Open the fuel valve on the welding torch handle and adjust the fuel

regulator delivery range.

12. Close the fuel control valve on the torch handle.

13. Momentarily depress the cutting oxygen lever to purge the high

pressure cutting oxygen passage.

14. Open the fuel valve on the torch handle approximately one-half

turn and ignite with a spark lighter.

NOTE: Wear protective goggles to shield the eyes from bright light.

15. Continue to increase the fuel supply at the torch handle until the

flame clears the end of the tip about 1/8”, then reduce the supply

slightly to return the flame to the tip.

16. Slowly open the preheat oxygen control valve on the cutting

attachment until the preheat flames establish a sharp inner cone.

17. Depress the cutting oxygen lever. Note that the preheat flame

changes slightly to a carburizing flame. Continue to depress the cutting

oxygen lever and increase the preheat oxygen at the cutting

attachment until the preheat flames are again neutral.

RECOMMENDED PROCEDURE FOR EFFIECIENT

FLAME CUTTING OF STEEL PLATE

Start to preheat, point tip at angle on edge plate

Rotate tip to upright position

Press oxy valve lever slowly, as cut starts, rotate tip backward slightly

Now rotate to upright position without moving tip forward

Rotate tip more to point slightly in direction of cut

Advance as fast as good cutting action will permit

Do not jerk; maintain slight leading angle toward direction of cut

Slow down, let cutting stream sever corner at bottom

Continue steady forward motion until tip has cleared end.

These steps above should adequately guide you to safely setting up

and using your cutting torch

Cut and prepare edge of materials

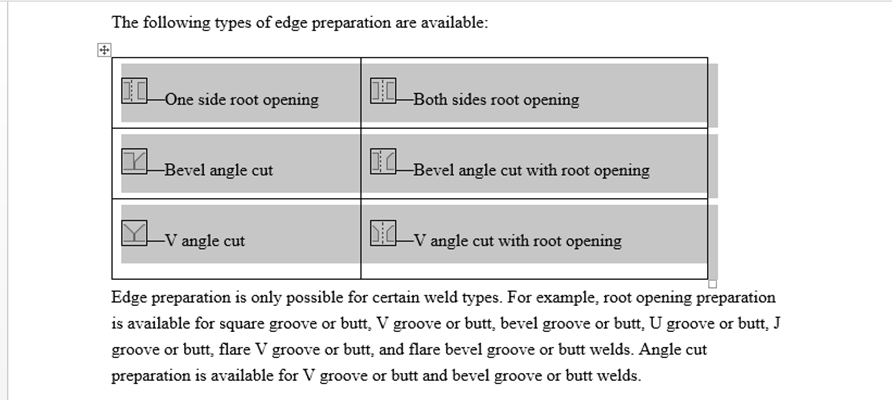

About the Edge Prep Welding Feature

Edge preparation consists of removing material along edges of metal

surfaces. You must prepare edges for welding when parts and

assemblies require certain strength. To achieve full welding

penetration, you must cut the edges of the metal. The weld replaces

the removed material and makes a complete bridge between the

joining parts.

Prepare welding consumables

In welding, using the correct consumable, or filler material, ensures a

strong bond between two metals. It is one of the four components to a

weld along with the metal being welded, the heat source, and the shield

from the air. As the metal gets heated to its melting point while being

shielded from the air, the consumable is added to the area being joined to

produce a single piece of metal. The role of the consumable in arc

welding is to not only fill in the seam, but also stabilize the flame of the

electric arc.

Types of Consumables

As you’ll learn in a welding program, the type of consumable used can vary

between a cored wire, solid wire, or rod electrode depending on the job.

Electrodes draw the necessary energy in order to perform welding

applications. 1

Pairing Consumables to Welding Processes

The American Welding Society has designated filler material specifications

and listed which welding processes each material can be used for. As you

can see from the chart, some of the filler materials should only be used in

one welding process, such as iron and steel gas welding rods for

Oxy-Acetylene (OA) welding. Below are a few different types of electrodes

used for some of the most common welding processes.

Shielded metal arc welding uses a powder-coated electrode (flux). When it

burns off, the coating shields the weld from oxygen. Filler metal is often

added to the coating to speed up the process.

Gas-tungsten arc welding uses a non-consumable tungsten rod to heat the

metal and filler metal. The rod just heats the metal and doesn’t add to the

filler material.

Gas metal arc welding is a process that uses a wire consumable with a wire

spool feeding the wire into the weld joint.

“Matching” Strength of Consumables to Metals

Along with ensuring the consumable has the same melting point as

the base metal, it’s also critical to match the strength of the filler to

the strength of the metals being welded to get the best results.

However, “matching” the strength of the base metal with the filler

material isn’t as simple as matching the strength classifications of

metals using a chart because base and filler metals have different

minimum yield and tensile strengths. The yield strength is the

amount of stress a material can handle before it starts to deform

plastically, while the tensile strength is the amount of stress a

material can take before it breaks.

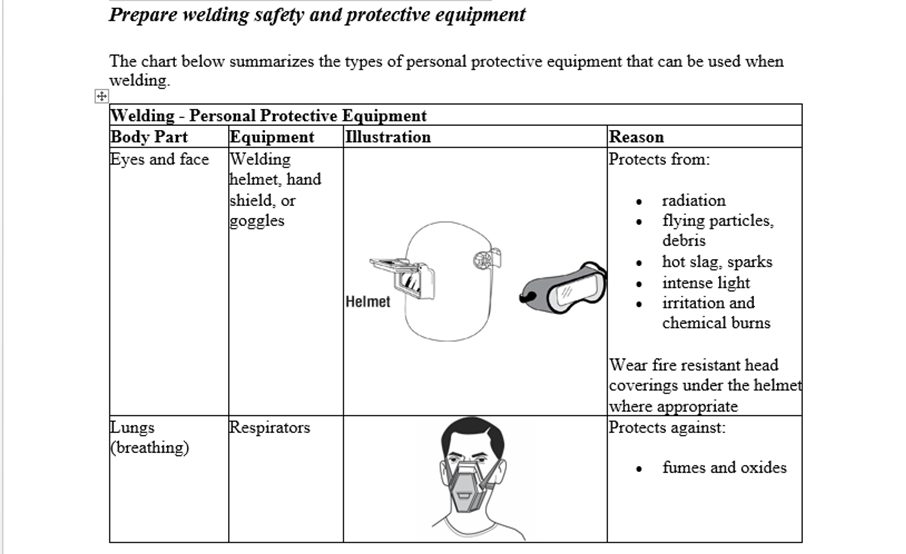

Why is eye protection important?

Eye injury can occur from the intense light and radiation that a

welding arc can produce. Eye injury can also occur from hot slag and

other metal debris that can fly off from the weld during cooling,

chipping or grinding.

Protect your eyes from welding light by wearing a welder's helmet

fitted with a filter shade that is suitable for the type of welding you

are doing.

ALWAYS wear safety glasses with side shields or goggles when

chipping or grinding a work piece if you are not wearing a welding

helmet.

The following operations require full face protection by using either a

welding helmet or a hand shield:

arc welding, plasma arc cutting, gouging or welding, and air carbon arc cutting.

For gas cutting, welding, or brazing, the intensity of the light is much

less than from arc welding, cutting or gouging processes. Lighter

shade filter lenses can be used with goggles in place of a helmet.

What are the various components of welding hand shields and helmets?

Hand shields or helmets provide eye protection by using an assembly of components:

Helmet shell - must be opaque to light and resistant to impact, heat and electricity.

Outer cover plate made of polycarbonate plastic which protects from radiation, impact and scratches.

Filter lens made of glass containing a filler which reduces the amount of light

passing through to the eyes. Filters are available in different shade numbers

ranging from 2 to 14. The higher the number, the darker the filter and the less

light passes through the lens.

Clear retainer lens made of plastic prevents any broken pieces of the filter lens

from reaching the eye.

Gasket made of heat insulating material between the cover lens and the filter lens

protects the lens from sudden heat changes which could cause it to break. In

some models the heat insulation is provided by the frame mount instead of a

separate gasket.

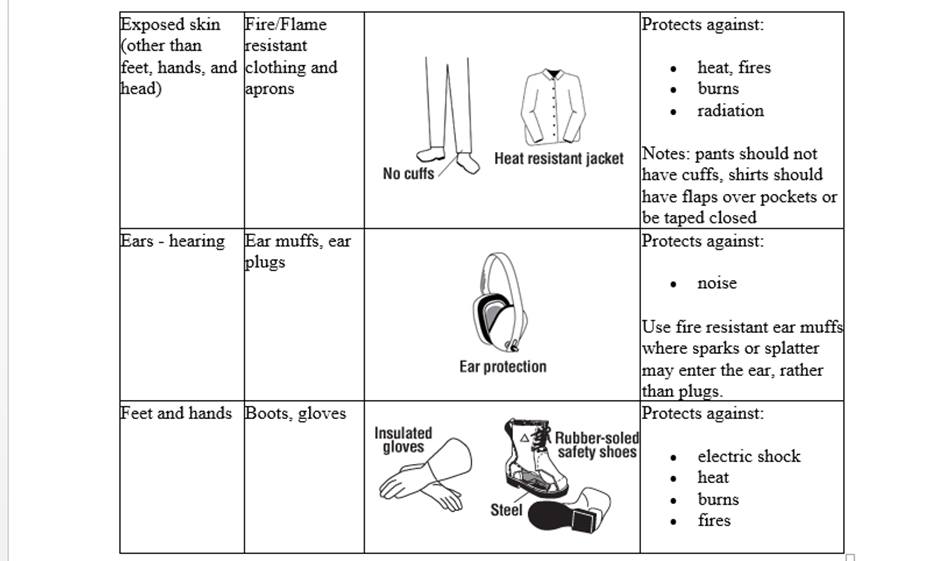

What are some tips to know when using protective clothing?

DO

Wear clothing made from heavyweight, tightly woven, 100% wool or cotton to

protect from UV radiation, hot metal, sparks and open flames. Flame retardant

treatments become less effective with repeated laundering.

Keep clothing clean and free of oils, greases and combustible contaminants.

Wear long-sleeved shirts with buttoned cuffs and a collar to protect the neck.

Dark colours prevent light reflection.

Tape shirt pockets closed to avoid collecting sparks or hot metal or keep them covered with flaps.

Pant legs must not have cuffs and must cover the tops of the boots. Cuffs can collect sparks.

Repair all frayed edges, tears or holes in clothing.

Wear high top boots fully laced to prevent sparks from entering into the boots.

Use fire-resistant boot protectors or spats strapped around the pant legs and boot tops, to prevent sparks from bouncing in the top of the boots.

Remove all ignition sources such as matches and butane lighters from pockets. Hot welding sparks may light the matches or ignite leaking lighter fuel.

Wear gauntlet-type cuff leather gloves or protective sleeves of similar material, to protect wrists and forearms. Leather is a good electrical

insulator if kept dry.

Using a shield can help keep any sparks spray away from your clothing.

Wear leather aprons to protect your chest and lap from sparks when standing or sitting.

Wear layers of clothing. To prevent sweating, avoid overdressing in cold weather. Sweaty clothes cause rapid heat loss. Leather welding

jackets are not very breathable and can make you sweat if you are overdressed.

Wear a fire-resistant skull cap or balaclava hood under your helmet to protect your head from burns and UV radiation.

Wear a welder's face shield to protect your face from radiation and flying particles.

DO NOT

Do not wear rings or other jewelry.

Do not wear clothing made from synthetic or synthetic blends. The synthetic fabric can burn vigorously, melt and produce bad skin burns